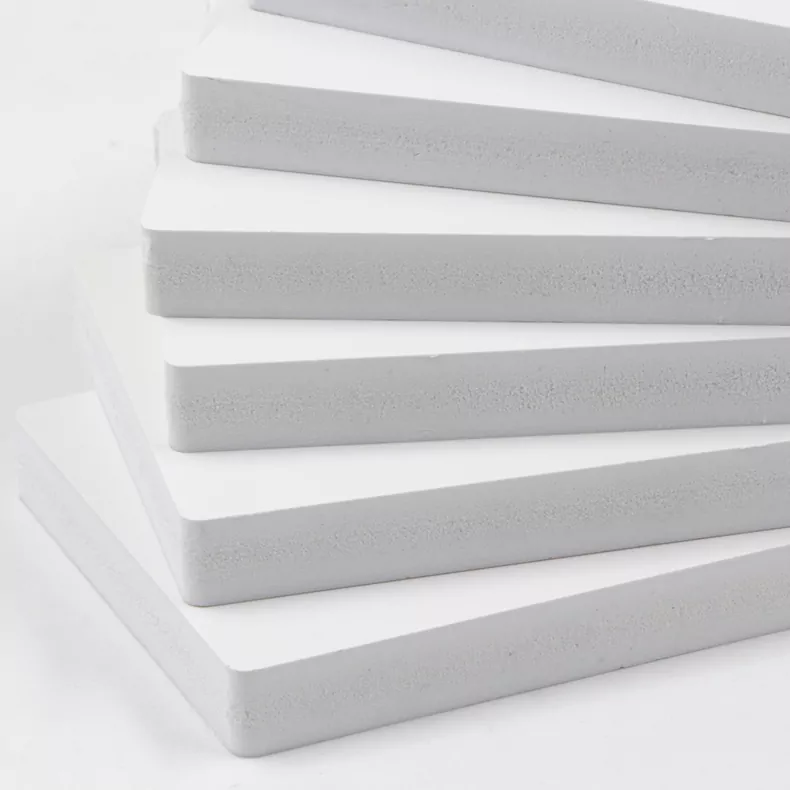

Introduction And Production Process Of PVC Foam Board

2025-05-19

Foamed plastic is a composite material containing plastic as a basic component, which can be said to be filled with gas. Classification of PVC foam board according to the expansion rate, it can be divided into high foaming and low foaming. According to the softness and hardness of the foam texture, it can be divided into rigid, semi-rigid and flexible foam. According to the cell structure, it can be divided into closed-cell foam and open-cell foam. Commonly used PVC foam boards are rigid closed-cell low-foam boards. Application of PVC foam board: PVC foam sheet has the advantages of chemical resistance, weather resistance, flame resistance, etc., and is widely used in display boards, signs, billboards, partitions, building boards and furniture boards. Key factors for evaluating the quality of foamed boards For foam materials, the size and uniformity of the cells are the key factors affecting the quality of the sheet.

For the low expansion foam board, the cells are small and uniform, and the foam board has good toughness, high strength and good surface quality. From the viewpoint of reducing the density of the foamed sheet, only the cells are small and uniform, and the density may be further reduced. When the bubbles are large and dispersed, it is difficult to further reduce the density. The key points of PVC foaming process control Plastic foaming molding is divided into three processes: the formation of bubble cores, the expansion of bubble cores and the solidification of bubbles. For PVC foamed sheets with chemical foaming agents, the expansion of the foam core plays a decisive role in the quality of the foamed sheet. PVC is a linear molecule with short molecular chains and low melt strength.

In the process of expanding the bubble core into bubbles, the melt is not enough to cover the bubbles, and the gas easily overflows into large bubbles, which reduces the product quality of the foamed sheet. The key factor to improve the quality of PVC foam board is to improve the melt strength of PVC. There are many ways to improve the melt strength of PVC from analyzing the processing characteristics of polymer materials. The effective method is to add additives to increase the melt strength and reduce the processing temperature. PVC is an amorphous material. As the melt temperature increases, the melt strength decreases. Conversely, as the melt temperature decreases, the melt strength decreases, but the cooling effect is limited to support.

The role of processing aids in PVC foam boards Processing aids promote the melting of PVC, improve surface finish, improve melt elasticity, and enhance melt elongation and strength. It helps cover air bubbles and prevents cells from collapsing. The molecular weight and dosage of the foaming regulator have a great impact on the density of the foamed sheet: as the molecular weight increases, the melt strength of PVC increases, the density of the foamed sheet can be reduced, and the amount of adjustment also increases. This effect has no linear relationship. Continuing to increase the molecular weight or increase the effect on decreasing the density is not very obvious, and the density tends to be constant. There is an important relationship between foaming regulators and foaming agents. The density of the foamed sheet and foaming regulator has an equilibrium point. Outside this equilibrium point, the density of the foamed sheet is not affected by the content of the foaming agent. Keep PVC foam board constant, i.e. increasing the amount of blowing agent will not decrease the density. This is because the melt strength of PVC is limited by a certain amount of foaming regulator, and the excessive gas causes the battery to collapse or merge. If you want to know more about the foamed board, please contact the PVC foamed board manufacturer in time. We will update the relevant information on your website regularly. Please pay attention to it.